Heat exchangers

|

Air preheatersAir preheaters are heat exchangers that are mainly designed for use in the combustion air preheating of power plant. TUBETECH supplies and delivers the heat exchangers designed as finned-tube heat exchangers or bare-tube heat exchangers respectively.The complete engineering including the process or mechanical design will be done by TUBETECH in a customer-oriented manner. The heat exchangers will be produced at the facility in Plauen «Made in Germany». Other accessories such as bypass valves, cleaning channels or supporting structures will also be planned, supplied and delivered by TUBETECH. |

|

Spare tube bundles

Over the years, TUBETECH has built up a reputation on the spare parts market for air-cooled heat exchangers. |

|

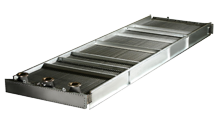

Finned tube bundles

Suction coolers, intermediate coolers, stepped coolers or aftercoolers are used to increase or maintain respectively performance characteristics of gas compressors, air compressors, turbines, generators or large motors. These are water-cooled finned tube heat exchangers designed to cool the intake air, compressed air or other industrial gases such as oxygen, hydrogen, chlorine or similar. Here, the cooling water flows inside the tubes and the gaseous fluid to be cooled flows around the finned tubes. |

|

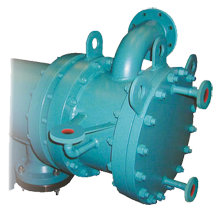

Bundle heat exchangersThese products are being successfully used throughout the world. They can be designed and manufactured to any national or international code or standard.The complete engineering including process design and manufacture are implemented in a customer-oriented manner by the center of excellence of Gesellschaft für OELTECHNIK mbH. |