Finned tubes

The finned tube production process is a continuous process. Pre-lengthened tubes are connected to each other so that the fining machine sees an endless tube. Besides an increased output, this allows the repetition of fin parameters going from one tube to the others for the hole tube batch.

TUBETECH's high fin product line contains finned tubes of different designs up to a length of 15 m. A vast variety of material combination for fin and tube allows to address different requirements.

Finned tubes find application in TUBETECH air-cooled heat exchangers and TUBETECH heat exchangers.

PARAMETERS OF SPIRALLY WRAPPED FINNED TUBES

| Outside diameter core tube: | 15 - 51mm |

| Diameter of the fins: | 28 - 82mm |

| Fin spacing: | 2 - 6mm freely selectable |

| Tube products overview: | Bi-Metallic (E-Fin / extruded), G-Fin, L-Fin / KL-Fin (also tinned), I-Fin (hot-dip galvanised, also tinned) |

| Material of core tube: | Copper, Cu-Ni-alloying, brass, carbon steel, stainless steel, titan |

| Material of fins: | Copper, Aluminium, carbon steel, steel zinced |

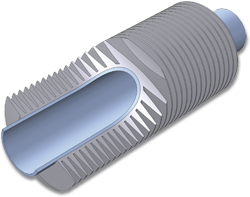

BI-METALLIC (E-Fin / extruded) |

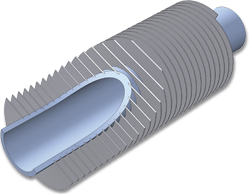

G-FIN |

| The fins are formed by extrusion from an aluminium outer tube onto the host tube. This results in a very good contact between the host tube and the fin and an efficient corrosion protection. Application temperature: max. 300°C Material combinations: Core tube: all metals Fin: Aluminium |

The fin is wrapped under tension and mechanically embedded in a groove, which was spirally cut into the outside surface of the tube. This results in a good, permanent bond between the fin and the tube. Application temperature: max 400°C Material combinations: Core tube: Carbon steel, stainless steel Fin: Carbon steel, aluminium |

|

|

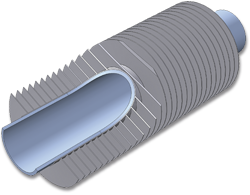

L-FIN / KL-FIN (also tinned) |

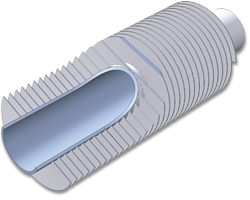

I-FIN (galvanised, also tinned) |

| An L-shaped band is spirally wrapped under tension over the outside surface of a tube. This results in a large contact area between the fin and the tube. Application temperature: max. 130°C/max. 200°C Material combinations: Core tube: Carbon steel, stainless steel, duplex Fin: Aluminium |

A band is spirally wrapped under tension over the outside surface of a tube. The special feature here is the corrugated fin foot, which enlarges the contact area between the fin and the tube. In addition, the fin is galvanized onto the tube for efficient heat transfer and excellent corrosion protection. Application temperature: max. 380°C Material combinations: Core tube: Carbon steel, stainless steel Fin: Carbon steel |

|

|

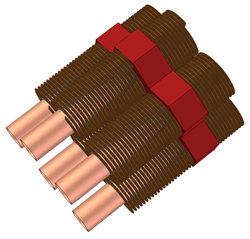

hexagonal silicone spacer |

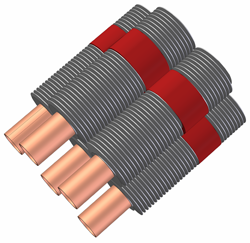

circular silicone spacer |

| The hexagonal red silicone spacer is casted around pre-specified locations. It allows to position the individual tubes in the bundle to form a triangular 60° tube pitch. The silicone rubber material of the spacers absorbs vibration, allows for a rigid bundle construction, and pre-positions tubes for insertion in tube sheets. | The circular red silicone rubber spacer is an alternative to the hexagon spacer. The shock absorbing feature remains while the tubes can be turned 360° around the longitudinal axis. The location and the outer diameter of the spacer are determined by the designer of the bundles. |

|

|

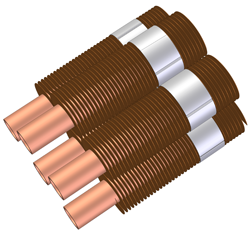

Copper spacers |

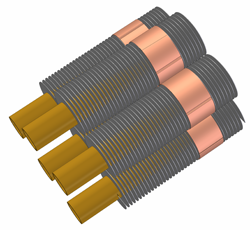

Aluminium spacers and others |

| Copper sheet metall ring spacers wrapped and secured around the high fin serve as a point of support. Prior to tightening the bundle a slight axial movement of tubes against each other is possible. The copper spacer protects the finned tubes from interferring with each other. | For application where copper as a spacer material is not desired, the sheet metall ring can be made of aluminium. Any other kind of spacer systems are available upon request. |

|

|

PARAMETERS OF PLATE FIN TUBES

| Materials: | Copper, Cu-Ni, brass |